Standard Series

The heater unit is mounted within the AHU adjacent to other components. The heater unit becomes simply one module of the AHU assembly. To ensure heater terminals are not exposed to flowing air, they are terminated in IP:5x terminal boxes. Each heater stage is spread over the entire face area to take advantage of all available airflow.

When the heater unit is installed entirely within the unit, only thermal cutouts & field terminals are built into the unit. A remote panel is provided for controls.

The rail coach industry has developed tough standards to overcome the severe vibration, shock, and high operating voltages that routinely occur. KEPL has built heater units to meet these standards. We use oversized heaters and terminal supports and corrosion-resistant stainless steel frames. These features help to protect the heater units from the harsh environment and ensure that they are able to perform well over a long period of time without needing to be replaced.

KEPL has developed heaters suitable for round ducts. The duct heater is supplied with two square-to-round galvanized steel transitions for field installation. These sheet metal transitions are attached directly to the heater flanges and to the round duct using screws. This provides uniform airflow across the elements to avoid hot spots, which could affect the performance of the heater.

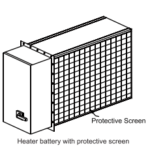

Protective screens protect personnel from accidental contact with electrically hot elements and prevent large airborne contamination from reaching the elements. Both sides of the heater can be fitted with a 10mm wire mesh protective screen.